Ever wondered what is going on inside the electrical components of your organisation?

Electrical failures are more than just a nuisance when you are trying to keep a business running smoothly. They are a risk to your people, your productivity and your bottom line.

That’s why staying ahead of potential issues hidden deep within your systems is critical.

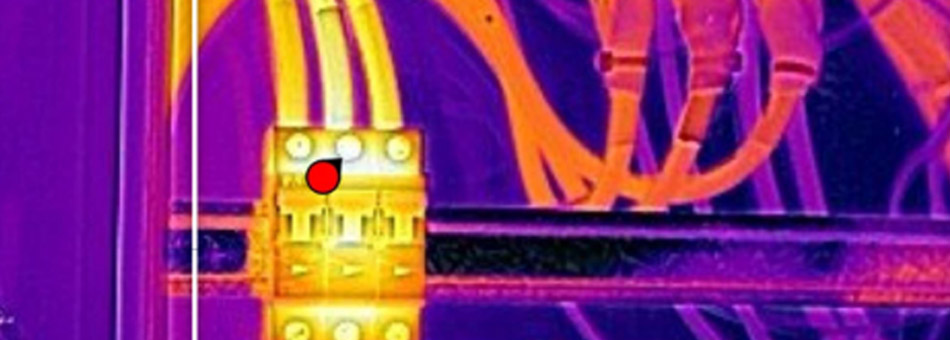

No, you don’t have to be Superman with x-ray vision to see what is going on in there. Thermal imaging literally gives you a peek inside those components and casings.

We use thermal imaging as a non-invasive diagnostic tool to spot problems before they become disasters.

From overloaded circuits to deteriorating switchboards, thermal inspections can help detect potential faults early. Early enough to prevent system failures, fires, or costly shutdowns.

Let’s explore what thermal imaging is and how it could be your secret productivity weapon!

Why Thermal Imaging?

Electrical faults are rarely visible to the naked eye. Traditional inspections might miss them altogether. However, when thermal imaging is used, we can “see” the heat signatures of any components that might be under stress. This can provide insights into systems that are running too hot, too inefficiently, or too close to failure.

Having this vital information means:

- No interruptions to your operations

- No need to dismantle equipment to find out what’s going on

- Access to immediate actionable data

Thermal imaging can be helpful in all kinds of commercial and industrial settings. Whether you have a large commercial operation, a manufacturing facility or a large office complex, thermal imaging can help you maintain consistent operations, reduce risks, and give you the ability to make informed maintenance decisions. It does all of this without disruption to your day-to-day.

What Does Thermal Imaging Detect?

There are plenty of things that thermal imaging can identify. Some of the most common are:

- Loose or corroded connections

- Overloaded circuits

- Failing components in switchboards and control panels

- Imbalanced loads

- Hotspots caused by excessive resistance

- Degradation from age or poor installation

Easily missed, these issues can all lead to breakdowns, fire hazards and costly damage if left unchecked.

Reporting On The Unknown

Conducting thermal imaging is not much use without a report on the findings! So, after every thermal imaging inspection, DGE delivers a Condition Report Checklist. It’s a clear, client-friendly document that helps you understand the current state of your electrical infrastructure.

The report includes:

- A summary of inspection findings

- Thermal images highlighting areas of concern

- Risk categorisation (low, moderate, high)

- Recommendations for repair, upgrade or continued monitoring

- A prioritised action plan for future-proofing your assets

It’s more than just a report. I can actually be a roadmap for smarter, safer management of your operations.

Maintaining Site Compliance

Keeping your site compliant with electrical safety regulations isn’t an optional kind of thing! Luckily, thermal imaging helps make compliance proactive and stress-free. By detecting faults early, you reduce the risk of sudden equipment failure and also comply with WorkSafe and health and safety regulations.

It may even save you money. Many insurers now recommend thermal imaging as part of a risk management plan. So, having a thermal inspection report from DGE on hand can strengthen your case when negotiating insurance premiums or making a claim.

The Cost of Waiting vs The Value of Proactivity

So, the money thing. Is investing in thermal imaging worth it? The answer is a very definite yes!

While there is a cost associated with the process, the cost of proactive thermal imaging is very minor when compared to the expense of:

- Emergency electrical callouts

- Equipment replacement

- Loss of production or service due to downtime

- Fire safety incidents

- Insurance complications

When you really think about it, thermal inspections are a small investment to ensure long-term reliability in your operations and help you avoid large, unexpected expenses down the track.

Protect your People And Your Property

Thermal imaging is a vital part of future-focused facility management. It helps you to take control of your systems, reduce risks and plan with confidence.

Partnering with an expert provider like DGE will give you another layer of confidence. Choosing us means:

- Expertise you can trust: Our team is trained, qualified, and experienced in working across a wide range of commercial and industrial environments.

- Practical and proactive advice: We don’t just spot a problem and tell you about it. We’ll guide you through a practical solution also.

- All your electrical needs: From design and build to ongoing maintenance and diagnostics, We manage every aspect of your electrical systems.

- Clear Reporting: We keep things simple, clear and actional with our easy to understand reporting. That means you can make informed decisions quickly.

If you’re responsible for electrical compliance, asset reliability, or operational continuity, it’s time to give us a call!